I have not posted in awhile but thought I should start it up again. This one is about another Dual turntable problem and a solution for it. Hmm, that kind of makes it sound like Dual turntables have a lot of problems. That's sort of true, but they had a lot more turntables than most. More models and more in quantity sold too. Have a look at this page if you don't believe me:

http://www.dual-reference.com/tableinx.htm

So, the problem fix for the evening involved a Dual 510. The motor on the original version of the 510, and a few other models as well such as the 601 and 1249, had a tendency to run at twice the standard speed occasionally. This apparently did not happen on the Duals at home in Germany where the electricity from the wall is 240 volts at 50 HZ, but here in North America at 120 volts & 60 HZ it sometimes occurred. The motor in question was the SM-840. Later versions included the SM-840-2 and -4 and they had found a fix by then.

The motor runs at the right speed about 80% of the time and simply turning it off and back on usually makes it run at the correct speed. This is the second of these turntables I have had this issue with, and while you could live with it, I would rather make it go away.

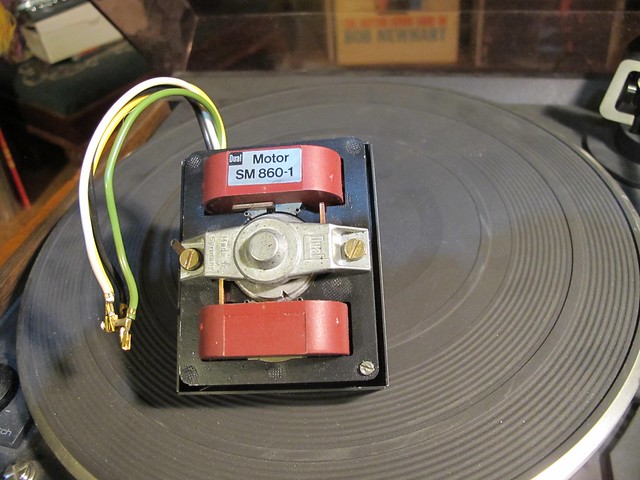

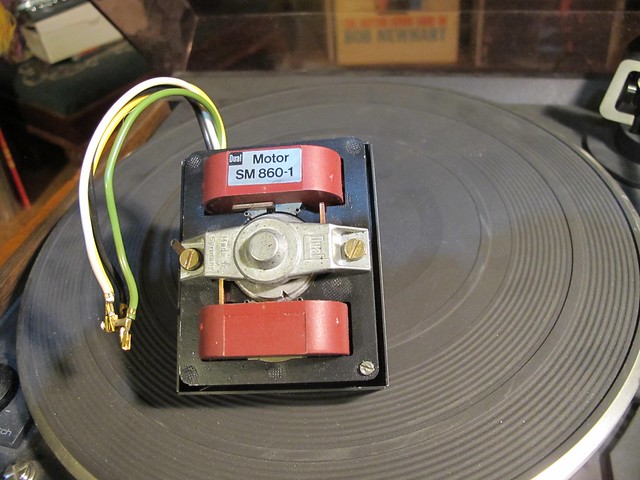

The later motor model SM-860 also fixed the problem, and a kind person on Audio Karma sent me one very inexpensively.

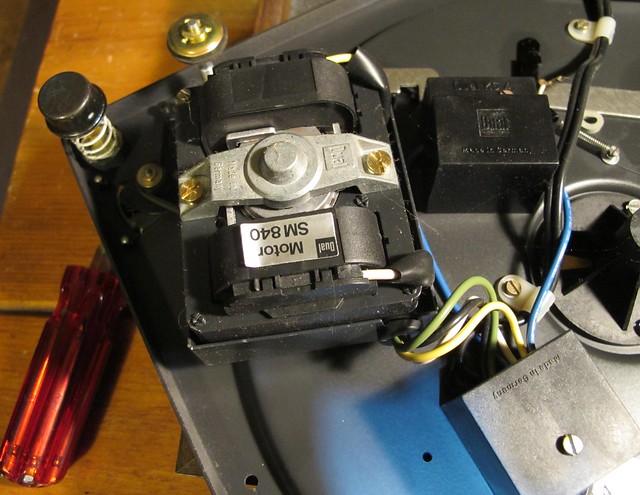

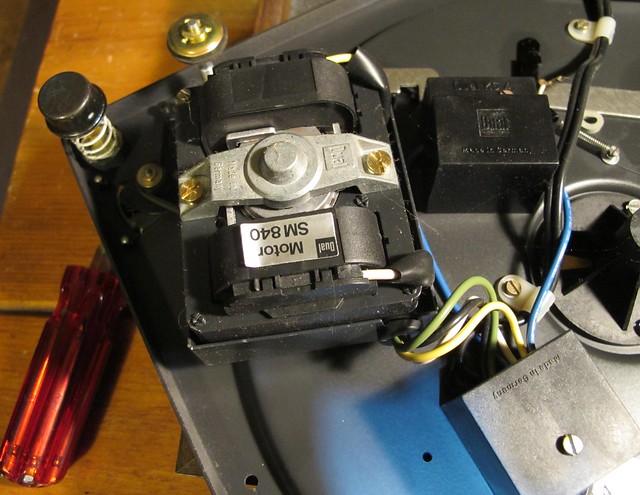

With the turntable flipped over (yeah I know, the picture could be flipped too) here is the original motor. I took out the 2 large screws and 1 small one on the motor, and removed the cover for the electrical connections.

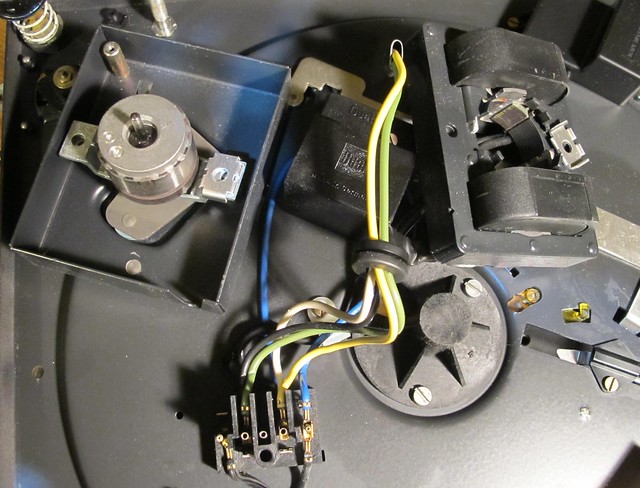

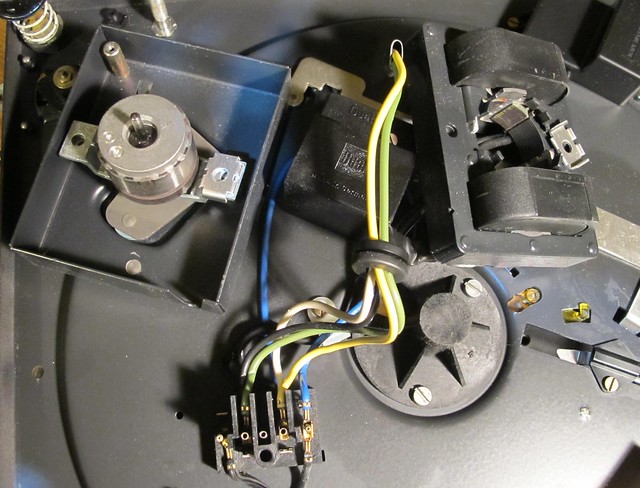

Swapping the entire motor is not required. You really only need to change the motor winding part which is off to the right in this pic. The entire motor can be taken out but there are several more screws and the pitch control belt to mess with if you do that. This is easier...sort of.

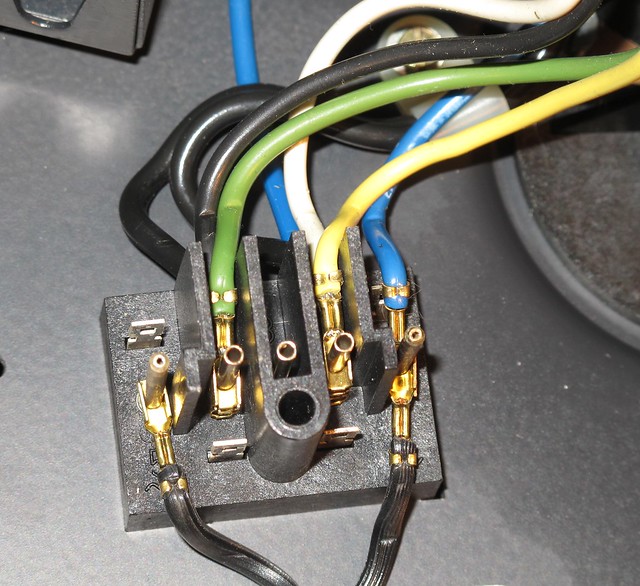

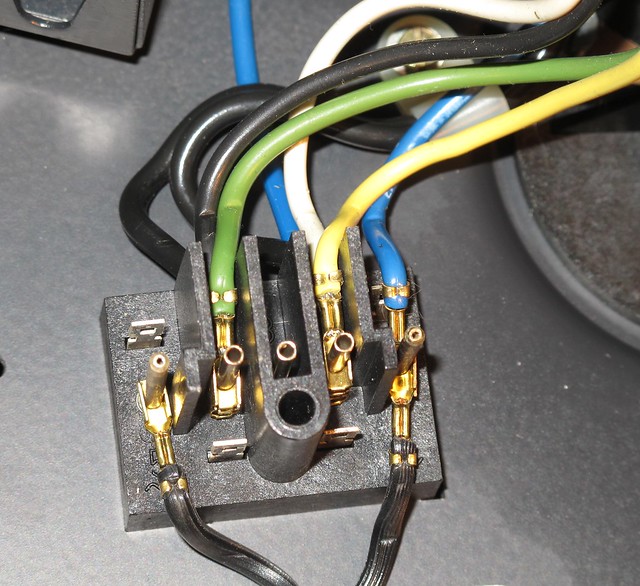

I often take close-ups of the wiring or other important details so I can make sure they go back the same way.

This is a good time to oil the motor bearings. Note the scarring on the armature. I'm not sure how that came about.

Top bearing with some fresh oil.

And going back together.

Fully reassembled, but I still had some fiddling to do. I found that there was a lot of stiffness in the motor and it barely turned under hand pressure and not at all with power applied. I played around with the tightness of the 2 bolts that hold the bearing mount and that did not help right away.

I swapped the armature from the 860 in place of the 840, thinking that maybe the scoring you see was a factor. The brass capstan was not at the same height though and I have trouble with those little screws before so changed it back to the original (on the right). This time when I put it back together it worked smoothly. It could have just been the orientation of the top and bottom bearings which are in kind of ball and socket joints.

Anyway, it all worked out! I cleaned the entire table up further, oiled the platter well, gave the lid a quick polish and here you go! Starting and stopping a bunch of times and the speed is just as it should be every time.

In this pic you can also see the cuing lever I made from a bicycle spoke and spoke nipple. That lever was missing as well and this stuff was handy.

It still has a few cosmetic issues but it looks good and works well.

http://www.dual-reference.com/tableinx.htm

So, the problem fix for the evening involved a Dual 510. The motor on the original version of the 510, and a few other models as well such as the 601 and 1249, had a tendency to run at twice the standard speed occasionally. This apparently did not happen on the Duals at home in Germany where the electricity from the wall is 240 volts at 50 HZ, but here in North America at 120 volts & 60 HZ it sometimes occurred. The motor in question was the SM-840. Later versions included the SM-840-2 and -4 and they had found a fix by then.

The motor runs at the right speed about 80% of the time and simply turning it off and back on usually makes it run at the correct speed. This is the second of these turntables I have had this issue with, and while you could live with it, I would rather make it go away.

The later motor model SM-860 also fixed the problem, and a kind person on Audio Karma sent me one very inexpensively.

With the turntable flipped over (yeah I know, the picture could be flipped too) here is the original motor. I took out the 2 large screws and 1 small one on the motor, and removed the cover for the electrical connections.

Swapping the entire motor is not required. You really only need to change the motor winding part which is off to the right in this pic. The entire motor can be taken out but there are several more screws and the pitch control belt to mess with if you do that. This is easier...sort of.

I often take close-ups of the wiring or other important details so I can make sure they go back the same way.

This is a good time to oil the motor bearings. Note the scarring on the armature. I'm not sure how that came about.

Top bearing with some fresh oil.

And going back together.

Fully reassembled, but I still had some fiddling to do. I found that there was a lot of stiffness in the motor and it barely turned under hand pressure and not at all with power applied. I played around with the tightness of the 2 bolts that hold the bearing mount and that did not help right away.

I swapped the armature from the 860 in place of the 840, thinking that maybe the scoring you see was a factor. The brass capstan was not at the same height though and I have trouble with those little screws before so changed it back to the original (on the right). This time when I put it back together it worked smoothly. It could have just been the orientation of the top and bottom bearings which are in kind of ball and socket joints.

Anyway, it all worked out! I cleaned the entire table up further, oiled the platter well, gave the lid a quick polish and here you go! Starting and stopping a bunch of times and the speed is just as it should be every time.

In this pic you can also see the cuing lever I made from a bicycle spoke and spoke nipple. That lever was missing as well and this stuff was handy.

It still has a few cosmetic issues but it looks good and works well.